Next-Generation Microbatteries: How Solid-State Cells Will Transform Consumer Electronics

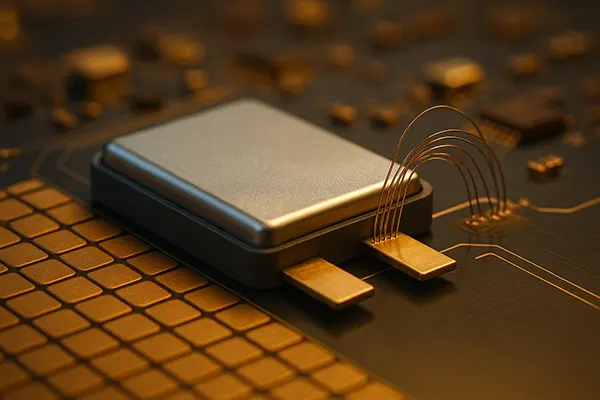

Solid-state microbatteries have emerged as one of the most significant technological shifts in compact power storage. Their structure, durability and long-term reliability are reshaping expectations for devices where size, efficiency and safety are essential. As consumer electronics continue to shrink while demanding higher performance, next-generation solid-state cells are becoming a practical solution for industries that rely on stable and scalable energy sources.

Advantages of Solid-State Microbatteries in Modern Devices

Solid-state microbatteries differ from traditional lithium-ion cells by replacing liquid electrolytes with solid materials, usually ceramic or polymer-based. This structural change allows for greater resistance to temperature fluctuations and mechanical stress. Manufacturers are increasingly adopting these designs, as they significantly reduce the risk of leakage or spontaneous degradation over long-term use.

The energy density of solid-state microbatteries is consistently increasing due to progress in thin-film manufacturing and improved electrode materials. In 2025, several commercial prototypes demonstrate storage capacities 30–40% higher compared to miniature lithium-ion alternatives of similar size. This advantage is especially relevant for compact wearables, medical sensors and IoT modules that require stable, low-maintenance power solutions.

Another benefit is the extended service life. Many solid-state microbatteries maintain up to 80% of their capacity after thousands of charge cycles. The absence of liquid components reduces internal chemical reactions that normally accelerate ageing. As a result, long-lifespan devices benefit from reduced maintenance and replacement costs.

How Solid-State Design Improves Reliability

The enhanced reliability of these microbatteries is linked to the solid electrolyte’s stability. It prevents internal short circuits and enables controlled ion movement during charging and discharging. This stability contributes to consistent performance even in environments where temperature shifts or mechanical shocks are common.

Compact devices frequently experience vibration, bending or pressure during everyday use. Solid-state microbatteries are less susceptible to deformation-related damage because their internal layers are bonded more rigidly. This design approach ensures that power delivery remains predictable, even when built into flexible electronics or ultra-small sensor housings.

Manufacturers also emphasise safety improvements. Without flammable organic liquids, the probability of thermal runaway is significantly lower. This feature supports broader adoption in medical implants, industrial micro-sensors and remote monitoring systems that require absolute operational safety.

Applications in Wearables, IoT and Healthcare Devices

The shift towards compact and energy-efficient components has made solid-state microbatteries ideal for wearables. Fitness trackers, biometric patches and smart jewellery often demand long operating times while maintaining minimal weight. The enhanced energy density and longevity of solid-state cells ensure consistent performance across long usage periods.

For healthcare, reliable operation is essential. Solid-state microbatteries are now used in disposable medical sensors, monitoring patches and certain types of implantable micro-devices. Their stable chemistry reduces the risk of unpredictable discharge behaviour, making them suitable for long-term physiological monitoring.

IoT devices depend heavily on low-power consumption, especially those deployed in remote environments. Solid-state microbatteries offer extended lifespan, making them suitable for sensor networks, logistics trackers and miniaturised automation tools. Their predictable performance is especially valuable in infrastructures where battery replacement is difficult.

Market Expansion and Industrial Adoption

By 2025, commercial adoption has grown notably due to improvements in scalable manufacturing. Investments in thin-film production lines and refined deposition techniques have reduced costs and enabled mass production for consumer and industrial markets. As a result, more companies integrate solid-state solutions into product lines requiring reliable miniature power sources.

Research laboratories and tech firms continue to refine cathode and anode materials to achieve even higher storage densities. Advanced lithium-metal and sulphide-based structures are being tested to accelerate ion movement and minimise resistance. These innovations are expected to improve both power output and fast-charging capabilities.

The supply chain is gradually adapting as well. Producers of semiconductors and microelectronics increasingly partner with battery developers to integrate solid-state cells directly during component manufacturing. This approach simplifies assembly, reduces material waste and ensures compatibility with compact device designs.

Future Potential and Technological Challenges

Although solid-state microbatteries are progressing rapidly, several technical challenges remain. One key limitation concerns the interface between the solid electrolyte and metallic electrodes. Over time, microscopic cracks or interface resistance can affect overall performance, especially under high current loads. Researchers are testing flexible electrolyte blends to mitigate these issues.

Another factor is production cost. While manufacturing has become more efficient, thin-film technology still requires specialised equipment and precision control. As demand increases across automotive, medical and consumer sectors, cost reductions are expected through process optimisation and broader adoption of automated fabrication systems.

Despite these challenges, the trajectory of development is clear. Advances in material science and scalable production are bringing solid-state microbatteries closer to becoming a standard component in compact electronics. Their combination of durability, safety and improved energy efficiency positions them as a long-term solution for next-generation devices.

What to Expect in the Coming Years

Future generations of solid-state microbatteries will likely incorporate hybrid materials that improve ion transport while maintaining structural stability. These materials may allow even thinner cells with higher energy densities suitable for ultra-compact wearables and precision instruments.

Standardisation across the industry is also progressing. Collaborative efforts between manufacturers aim to create unified specifications for size, capacity and testing procedures. This consistency will simplify integration for device developers and support broader commercial use.

Market forecasts indicate that demand will grow considerably as more sectors adopt miniaturised electronics. While mass adoption depends on addressing cost and manufacturing constraints, current advancements suggest that solid-state microbatteries are well-positioned to become a key energy solution across multiple industries.